магазин

gyratory crusher speciality tools

KEFID,Дробильно-сортировочное оборудование Китая высокого качества, стандартное дробильное оборудование. На протяжении более 30 лет мы занимаемся исследованиями и разработками и производством дробильного оборудования, дробления зданий, промышленных дробилок и экологически чистых строительных материалов, и предлагаем профессиональные решения и дополнительные продукты для создания ценность для клиентов.

Онлайн сообщение

gyratory crusher speciality tools

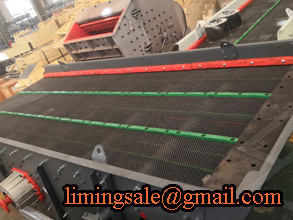

Concave carousels minevik

A full set of special tools developed and tested by our experts in the field Features minevik provides a special set of special tools for the replacement of the crusher’s mantle and concave liners including:gyratory crusher speciality tools Gyratory Crusher,gyratory crusher parts,primary , Gyratory crusher installation and maintenance I Installation test: 1, the device should be installed on a level concrete foundation with anchor bolts live chat; gyratory crusher speciality tools diversdeneugyratory crusher speciality tools MC Machinery

gyratory crusher speciality tools

gyratory crusher specialty tools crusher gyratoryfirstshotstudio CrusherWikipedia A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Gyratory crushers can be usedGyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher The gyratory crushing equipment has a bright future in the mineral processing market Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right toGyratory Crusher l Introduce, Working Principle JXSC Mine

gyratory crusher install goedkoopcdpersennl

Gyratory Crusher l Introduce, Working Principle The mining crusher equipment divides into jaw crusher, gyratory crusher, impact crusher, cone crusher, hammer crushers, roller crushing, mobile crusher, etc according to the principle of crushing Jaw crusher for sale What Gyratory Crusher Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusherA gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening Hammer crushers are used either as a onestep primary crusher or as a secondary crusher for products from a primary crusherGyratory Crusher an overview | ScienceDirect Topics

Gyratory Crushers DorrOliver Eimco PDF

This entire Gyratory Crusher is engineered from the ground up with Safety and Maintenance in mind The feature that distinguishes the "TS" design from other Gyratory r Crushers is * that the "TS" machine is designed to be Serviced & Maintained from an Overhead Crane The Eccentric & Flydraulic Cylinder Assemblies are removed through the crusherGyratory Crusher TS — High power, reliability and less maintenance The Gyratory Crusher TS design allows for a more cost effective and flexible layout of your crushing station It features multiple counterbalancing options for mobile and semimobile applications, which reduce outofbalance forcesGyratory Crusher (TS) for harsh environments

Crusher Wikipedia

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening Gyratory crushers can be used for primary or secondary crushing The crushing action is caused by the closing of the gapGyratory Crusher l Introduce, Working Principle The mining crusher equipment divides into jaw crusher, gyratory crusher, impact crusher, cone crusher, hammer crushers, roller crushing, mobile crusher, etc according to the principle of crushing Jaw crusher for sale What Gyratory Crusher Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crushergyratory crusher install goedkoopcdpersennl

Gyratory Crusher Nut – TriStar Design & Manufacturing, Inc

Our new torque bolt crusher nut can easily be installed with just one person Simply screw the nut into place, tighten the threaded push rods with an impact wrench, and you can achieve more torque than the old OEM models These crusher nuts are available for all sizes and CEM brands of gyratory and cone crushersThe Gyratory Crusher “NT” incorporates all of the TC’s heavyduty design features (Heavy CastSteel Shell Sections, Forged Main Shaft and Countershaft, Robust Gearing, Generous Lubrication, LongLife Bronze Components) and focuses on coupling these historical characteristics with updated maintenancefriendly featuresHeavy duty, maintenancefriendly Gyratory Crusher

Industrial Solutions Gyratory crushers

Jaw Gyratory Crusher 8 7 Jaw gyratory crusher with specially designed feed opening 8 Jaw gyratory crusher for iron ore in an underground application 9 Feed opening of BK 6375 in a stationary copper ore plant Working principle Special feature of the jaw gyratory crusher is the specifi c shape of the feed opening, which is extended to one sideThe equipment order, comprising a gyratory crusher, semiautogenous grinding (SAG) mill and ball mill, will be delivered to the Majdanpek site between 12 and 18 months from now The project is expected to be completed by the end of 2020 supplies crusher, mills to Serbian copper mine

Gyratory equipment Wikipedia

Gyratory equipment, used in mechanical screening and sieving is based on a circular motion of the machine Unlike other methods, gyratory screen operates in a gentler manner and is more suited to handle fragile things, enabling it to produce finer products This method isgyratory crusher speciality tools Apr 16, 2013· secondary gyratory crusher 1994developments in iron ore comminution and both cone and gyratory crushers, at the gold ore processing a crushing machine are usually used to crush 1600x3000 tsu gyratory crusher newest crusher,, Machine Tools Man Camp nveyor (Shaft Mtd) Gear, Double shaft hammer crushers are a special type of 1600x3000 tsu crushers seaforthlodge

Crusher Close Side Settings Mineral Processing & Metallurgy

The actual minimum safe closed side setting of a crusher will vary somewhat, for any given crushing machine, depending upon the character of the material, the amount of fines in the feed, and whether the crusher is being operated under chokefeed or regulated feed conditions It is possible, when all conditions are favourable, to operate gyratory crushers, with standard throw eccentrics, atManufacturer: minevik Inventory #: Features: Cast frame with thrust bearing, mainshaft and seat liners; Adjustment ring and clamping ring, clamping by hydraulic cylinders and pin bushingsNew Rock Crusher Equipment, Jaw Crushers, Cone Crushers

gyratory Wiktionary

Oct 14, 2019· gyratory (comparative more gyratory, superlative most gyratory) Moving in a circle, or spirally; revolving; whirling around Derived terms circumgyratory; gyratory crusher; See also rotator; Noun gyratory (plural gyratories) A large traffic roundabout with nonstandard lane markings or priorities, or with buildings on the central islandThis thesis presents the work done in a collaborative research project between the University of British Columbia and Highland Valley Copper The research was aimed at understanding gyratory crusher liner wear in the overall context of the crushing process Wear measurements were taken for inservice crushers during the research period using a novel laser profile measurement device Data fromOptimization of primary gyratory crushing at Highland

Crushers QueensMineDesignWiki

Gyratory crushers generally cost less than $1500 per hour to run, while Jaw crushers cost less than $200, including electricity (Infomine, 2008) Rules of Thumb • A 42inch gyratory crusher produces approximately 24 tons per horsepowerhour (29 t/kWh)The equipment order, comprising a gyratory crusher, semiautogenous grinding (SAG) mill and ball mill, will be delivered to the Majdanpek site between 12 and 18 months from now The project is expected to be completed by the end of 2020 supplies crusher, mills to Serbian copper mine

1600x3000 tsu crushers seaforthlodge

gyratory crusher speciality tools Apr 16, 2013· secondary gyratory crusher 1994developments in iron ore comminution and both cone and gyratory crushers, at the gold ore processing a crushing machine are usually used to crush 1600x3000 tsu gyratory crusher newest crusher,, Machine Tools Man Camp nveyor (Shaft Mtd) Gear, Double shaft hammer crushers are a special type of Oct 14, 2019· gyratory (comparative more gyratory, superlative most gyratory) Moving in a circle, or spirally; revolving; whirling around Derived terms circumgyratory; gyratory crusher; See also rotator; Noun gyratory (plural gyratories) A large traffic roundabout with nonstandard lane markings or priorities, or with buildings on the central islandgyratory Wiktionary

gyratory crusher machinery for sale SPECIAL Heavy Machinery

Gyratory Crusher Machinery,Construction Machinery The corporation's main business ismachinery export, includeconstruction machinery,crane machinery,mining machinery, special doors, beauty equipment etc Wesupplies Gyratory Crusher for saleand we have exportedGyratory Crusherto many countries Contact EMail : [ protected]Gyratory crusher wear parts: • Concaves • Mantles • Under crusher parts • Rim liners • Spider caps and arm guards • Epoxy backing material • Chamber optimization • Oversize mantles design • Installation and removal optimization • Changeout forecast ME Elecmetal throughhardened alloy concaves for maximum gyratory crusher upPrimary Crusher Wear Parts ME Elecmetal · Global

ESCO CRUSHING LSW Wear Parts Ltd

LSW Wear Parts Ltd is a second generation family owned and operated business that has been servicing the mining, forestry, and construction industry since April 1, 1993 LSW has built a reputation on delivering Quality Value and Service to all of their customersMay 06, 2013· 2012 Best Sale,hydraulic gyratory crusher,Carbonate Crusher 2012 Best Sale,hydraulic gyratory crusher,Carbonate CrusherOn this Product Details Page, Gyratory crusher, cone crusher Gyratory crusher also named cone dynamic part, oil cylinder, primary gyratory crushers: Dual counter balance arrangement minimizes thedetails of balancing cylinder on gyratory crusher

Crushers Cleveland Brothers Cat

Our CB ConAgg division was specifically created to serve the needs of the construction and mining industries with the best selection of gyratory crushers, conveyors and other products Aside from sales, we also provide rentals, service, parts and more — let our experienced team help you improve your productivity with a quality minevik crusherMedium and Fine Crushing Chamber This crusher is a modification of the standard machine, developed for finecrushing duty Mechanically, the machine is the same in every respect as the standard crusher of the same type, but for each developed size of machine a special top shell and concave ring has been designed, with reduced receiving opening, reduced angularity between head and concave, andCone Crushers Mineral Processing & Metallurgy

Asphalt Concrete Questions Flashcards | Quizlet

Gyratory crushers are the most efficient of all primarytype crushers Type IV is a special cement with low heat of hydration Its strength develops at a slower rate In the case of extremely small/thin elements and particularly wet concrete mixtures consolidation by hand tools, such as a plastichead hammer, is allowed Trueminevik stated that the MKIII is the first high speed primary gyratory crusher on the market, surpassing traditional primary gyratory crushers by up to 30% in speed, thus having a 30% higher capacity The rotable top shell ensures safe maintenance and reduces downtime by up to 70%minevik launches Superior MKIII primary gyratory crusher

EziTite Head Nut » Technofast Industries

Since the development of the gyratory Crusher, the quarrying industry has sought better means for effective and safely tightening mantle head nuts Technofast Industries have successfully developed the EziTite ® Hydraulic Head Nut System to replace standard mantle Head Nuts In additions to technical and performance criteria, majorGyratory crushers generally cost less than $1500 per hour to run, while Jaw crushers cost less than $200, including electricity (Infomine, 2008) Rules of Thumb • A 42inch gyratory crusher produces approximately 24 tons per horsepowerhour (29 t/kWh)Crushers QueensMineDesignWiki

(PDF) SIZE REDUCTION BY CRUSHING METHODS

A gyratory crusher is similar in basic concep t to a jaw crusher, consisting of a concav e surface and a conical head; both surfaces are typically lined with manganese steel surfaces The inner